Captiva Spine Receives Clearance to Market TowerLOX-EXT Extended Tab Pedicle Screws

Jupiter, FL, September 2018 – Captiva Spine, Inc., which designs, manufactures and distributes elegant and intuitive spine fusion solutions announced today it has received 510(k) clearance from the U.S. Food and Drug Administration (FDA) to market TowerLOX-EXT® MIS Extended Tab Pedicle Screw complementing its TowerLOX® MIS Pedicle Screw System.

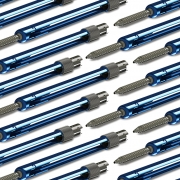

TowerLOX-EXT MIS Extended Tab Pedicle Screw

TowerLOX-EXT MIS Extended Tab Pedicle Screws provide the narrow insertion of an extended tab pedicle screw and the versatility, reliability, and security of a tower-based MIS pedicle screw. TowerLOX-EXT’s narrow insertion path coupled with TowerLOX’s patented articulating rod delivery/reduction options expand the capabilities of the system. Most notably, TowerLOX-EXT allows percutaneous tower attachment after the extended tabs have been removed, establishing a new standard for MIS pedicle screw systems. This is especially important intraoperatively, or for use when extending the fusion at a later date.

Dale Mitchell, President of Captiva Spine, stated “The design rationale and goals developed with our surgeon collaborators guided the creation of TowerLOX-EXT Extended Tab Pedicle Screw. Our intent was to reduce insertion pathway, eliminate counter-torque wound expansion, and retain the versatility provided by TowerLOX’s unique instrumentation for rod delivery, rod reduction, and spondylolisthesis reduction.”

TowerLOX® MIS Pedicle Screw System already supports MIS, mini-open, and open cases with simple and less invasive rod insertion (using patented Pivotec® Technology) and efficient internal/external rod reduction. TowerLOX-EXT screws provide 15mm of controlled built-in rod reduction above the break-off and in-situ tower attachment capabilities provide a MIS rescue/revision option not available with other extended tab systems.

Captiva Spine’s TowerLOX-EXT MIS Extended Tab Pedicle Screw is one of five new product launches that will be featured at Booth 1649 during the North American Spine Society (NASS) Annual Meeting held in Los Angeles, September 26-28, 2018.

Inquiries from tenured distribution professionals looking to partner with a company to build a relationship for the long run are always welcome.

For sales, contact:

Chip Jones, Director of Sales and Marketing

chip.jones@captivaspine.com or 561-277-9480 ext. 725

or via their website www.captivaspine.com/contact-us.

About Captiva Spine, Inc.

As a privately owned medical device organization founded in 2007, Captiva Spine supports spine surgeons, tenured spine distributors, and healthcare facilities in providing patients with progressive spinal care and an obsessive focus on quality. They strive to create and maintain sincere, honest, collaborative relationships. By valuing their relationships above all else, it fosters the mutual trust and openness needed for Captiva Spine to be a conduit of high quality, smart, elegant, and intuitive patient solutions. As a family of industry professionals, Captiva Spine takes pride in delivering these solutions responsibly and ethically while never losing sight of what they refer to as the Human Factor: Finding the joy in their daily lives and serving the needs of their customers with sincere, professional enthusiasm.

This Press Release can be found at PRWeb.com and is also featured on: OrthoSpineNews, Becker’s Spine Review, Spine-Market.com, TheSpineMarketGroup.com